What Does Conduit Do?

Learn all about conduit and how it works with this guide. Discover the importance and functions of conduit for electrical systems.

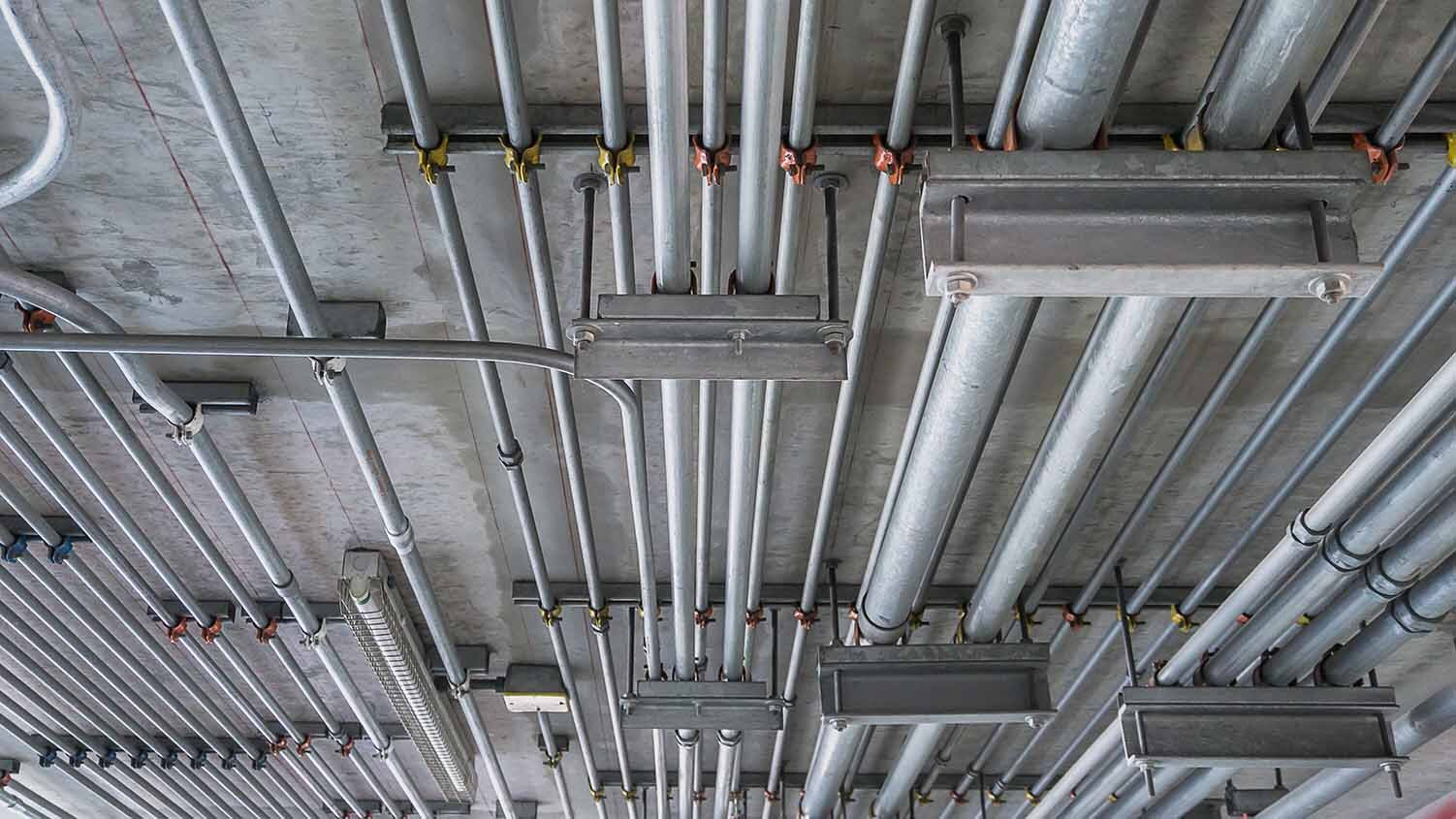

If you've ever seen the inside of a new building construction site, you likely noticed all the ductwork, plumbing, electrical wiring, and metal tubes running along, through, and above the interior studs before drywall is installed. What, exactly, are those metal tubes, you might wonder? The answer is simple: it's conduit.

Used in industrial, commercial, and residential applications, the conduit is simply the tubing—typically metal or plastic—used for electrical conductors, or electrical wires, to pass through. It provides protection to the conductor or wire, and to anyone who might come in close contact with it.

Conduit runs, or a conduit raceway, within buildings are installed for a variety of reasons, primarily to help electricians to cleanly and effectively run wiring throughout a building in a very organized manner. Raceways protect wires from humidity, heat, corrosion, water intrusion, and other potential physical damage to wiring. Additionally, conduit provides EMF shielding to reduce electromagnetic interference (EMI) from everyday electrical and power distribution systems, thereby protecting wires from outside "noise" that can negatively impact the wiring from working most effectively. And, along with making for very organized wiring, the conduit also serves as an equipment grounding conductor.

Conduit is available in a variety of materials based on the application, but regardless of what's used, it must be installed according to the National Electrical Code (NEC) and all applicable local codes within your community.

Different Types of Conduit

Conduit is generally installed with an array of compatible fittings (elbows, couplings, gaskets, compression fasteners, etc.) along with electrical boxes, which are often all made of the same or similar material.

As noted, it's available in different materials, as well as a number of different diameters, wall thicknesses, and lengths. These are some of the most common types of conduit used for wiring runs.

Rigid Metal Conduit (RMC) is used primarily in industrial applications and is a very durable, rugged conduit. With its thick-wall construction, RMC is made of heavy-duty galvanized steel. It is installed with threaded fittings and, due to its construction, it is not a conduit that can be easily bent with conduit benders. Typically sold in 10' and 20' lengths with threads on both ends, it can provide structural support for electrical panels, cables, and other equipment and is often used outdoors as it can withstand harsh environments while providing excellent protection to its internal components.

Intermediate Metal Conduit (IMC) is a lighter-weight, thin-walled version of RMC which is approved for use in the same applications as RMC. Since it's lighter and easier to work with than RMC, IMC is easy to bend with conduit benders and is more common in non-heavy-duty applications like new home construction.

Electrical Metallic Tubing (EMT) is a rigid conduit and typically made of galvanized steel. Also available in aluminum, EMT is also lightweight and thin-walled, so it can be easily bent with a conduit bender, regardless of the material it's made from. Unthreaded, EMT is installed and connected with fittings and couplings including compression-type fasteners or set screws. Commonly available in ½", ¾", and 1" diameters, it's used most often in light commercial and residential applications. It can be used outdoors; however, it would require watertight fittings when assembled.

Electrical Non-Metallic Tubing (ENT) is corrugated plastic tubing that is flexible, flame retardant, and moisture-resistant. It can't be installed in exposed locations, so ENT is commonly used inside walls. Since it bends easily and installs with glued plastic or snap-lock fittings, it's ideal for installation in standard wood- or metal-frame walls. Because of its versatility, ENT can also be installed inside concrete block structures and then covered with cement.

Liquid-Tight Flexible Metal Conduit (LFMC) is a flexible metal conduit similar to FMC in composition, except it has a plastic coating and is used with sealed fittings to make it watertight. LFMC is often used with outdoor equipment, such as an air conditioner unit.

Rigid PVC Conduit (PVC), or rigid polyvinyl chloride conduit, is the most common and often-used type of nonmetallic conduit. Very similar to PVC plastic plumbing pipe, it's installed with plastic fittings that are glued in place. Rigid PVC conduit is a popular choice as it's the lightest and easiest-to-use conduit available. And, because of its composition, it's very economical compared to many other conduit options. A variety of different sizes, wall thicknesses, and fittings make it versatile for a lot of different applications, especially corrosive environments and below-ground installations. The PVC conduit won't corrode like a metal conduit, and it remains stable in varying temperature extremes. In commercial and industrial applications, it can be buried underground as well as encased in concrete.

Installing the right conduit for your job or application not only ensures that the wiring is protected and safe, but when done properly, so is the property that all that wiring is snaking through.

Product Compliance and Suitability

The product statements contained in this guide are intended for general informational purposes only. Such product statements do not constitute a product recommendation or representation as to the appropriateness, accuracy, completeness, correctness or currentness of the information provided. Information provided in this guide does not replace the use by you of any manufacturer instructions, technical product manual, or other professional resource or adviser available to you. Always read, understand and follow all manufacturer instructions.